Code Based Conventional Roof Framing (SST Course)

I recently viewed a Course on the Simpson Strong-Tie Learning website titled `Code Requirements for Conventionally Framed Roofs. Good stuff! Kudos to Randy (`Author’). Per the Course, `Conventional Framed … ‘ means `Prescriptive’ framing, or, framing that does not require specific design by an engineer. It is characterized by the framing largely made up of multiple `repetitive’ parallel, equally-spaced, wood members, such as roof rafters and ceiling joists. It is also known as `stick framing’. The same goes for wall, floor, and foundation construction (except that foundations are often of continuous nature … concrete walls, footings, etc.). I learned some things from the Course. I also discovered that some of the clever framing in the house that I now live in … kinda followed conventional framing rather nicely … other of the framing definitely did not. (Yikes)

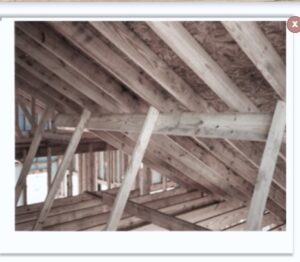

Pictured is a screen grab from the Course, showing an example of conventional roof framing, including the use of a purlin and brace.

The term `conventional’ means `in accordance with general agreement’, `established practice’, and so on. One might also say, with regard to conventional framing … `normal’ construction … `the way we’ve been doing roofs for years’. And this goes two ways in real life: 1) builders who build roofs unencumbered by codes, rules, engineers, etc., … framing them the way they `always have’, and 2) builders who build roofs according to the Building Codes. Those following the Building Codes have two options: one being Conventional, a.k.a. prescriptive, a.k.a. stick framing, and the other, engineered design. Conventional framing is covered by the International Residential Code (IRC), the Wood Frame Construction Manual (WFCM), and Section 2308 of the International Building Code (IBC). Again, the idea being, if one follows the `prescriptions’ in these codes, the employment of an engineer is not necessary. These requirements of these codes seem pretty restrictive, pretty `complicated’, but, I argue, they are generous in that they: 1) relieve you of having to hire an engineer (my contact information is here, somewhere, on the website), and 2) if you follow the requirements, you will not only be following the Code (probably also the law in the area you are building), but you will also be building a `safe’ roof. The requirements of the prescriptive codes are not trivial; nor are they intended to be unnecessarily burdensome or troublesome; they are the product of people coming together to come up with requirements that are both safe and workable in the modern world.

I tell my students, friends, relatives, etc. that are interested in building, or designing buildings, to learn where and how to apply conventional / prescriptive design; so you’ll be able to avoid hiring an engineer. (I am trying to retire.) Conventional design is generally applicable to residential structures. But learn it well, as not all residential structures fall within the limitations of the conventional provisions, and not all `parts’ of some residential structures can be designed (and built) `conventionally’. A bad-case scenario for a designer, or architect, is to embark on a project assumed to be covered nicely by conventional framing requirements, only to find out that an engineer must needs be employed, as the structure, or a part, or parts, fall outside the limitations of use of the prescriptive (`conventional’) provisions.

Another beauty of the conventional framing relates to the term `stick framing’. The roof, however large, can be made up of … `sticks!’ Yeah, pieces of wood that a single person can manage. So, not only may you avoid having to hire an engineer to design a `stick-built’ structure, you can avoid renting a crane, and hiring a crane operator, to put it together. Roof rafters, ties, ceiling joists, and so on, are of manageable size, and also typically available at the local building supply store. Further, the framing pieces are typically attached with nails, as opposed to bolts, or heavy hardware. (Neither do you need a welder!) Where bigger building elements are needed (beams, headers, girders), the prescriptive codes provide for their construction to be of `sticks’, e.g., by nail-laminating them together. (I have found, in fact, that when I have been framing alone, instead of nailing them together on the ground, and having to lift the (heavy) finished beam or header, the header can actually be installed piece by piece. Yay! No crane, no crying for the help of others in the moment!

(So, while I make a living as an engineer designing structures that fall outside of conventional framing, I actually do my living, making structures out of `sticks’.)

(Maybe I’ll pick apart my `conventionally framed’ house in another post.)

Oh, the IRC does provide for the use of roof trusses. The trusses are made up of multiple pieces of lumber, connected, typically, with metal plates (metal-plate connected wood trusses). They typically span from exterior wall to exterior wall, or from intermediate girder trusses to wall, and thus are `bigger’ than single rafters and joists. They are designed by a `truss manufacturer’, and are typically installed with the aid of cranes. You don’t have to hire an engineer to design manufactured roof trusses; the truss manufacturer does. The truss manufacturer typically provides site-specific design and layout, as well as the actual trusses. And the cost of the `engineering’ is part of the `truss package’.